PCD blanks for cutting tools

Category

PCD Blanks For Cutting Tools

Advisory

Advisory

Description

SF Diamond (SFD) manufactures 75mm diameter PCD cutting tool blanks in China.

SFD has equipped with many production facilities and inspection instruments for PCD cutting tool blanks, such as SEM, ultrasonic scanning technology (C-SCAN), etc. SFD also has capabilities of large-diameter PCD disc sintering, proven PCD surface processing, polishing and cutting technologies.

SF Diamond produces a wide selection range of PCD cutting tool blanks in disc and cut-segment for precision tooling industry. The available grain sizes are 1μm, 2μm, 5μm, 10μm, 25μm, and mixed grain sizes. PCD surface polished and non-polished are also available. Nonstandard products can be customized on request. A professional service team offers products, applications, and customized solutions to our customers, to assist customer in surface finish and tool life.

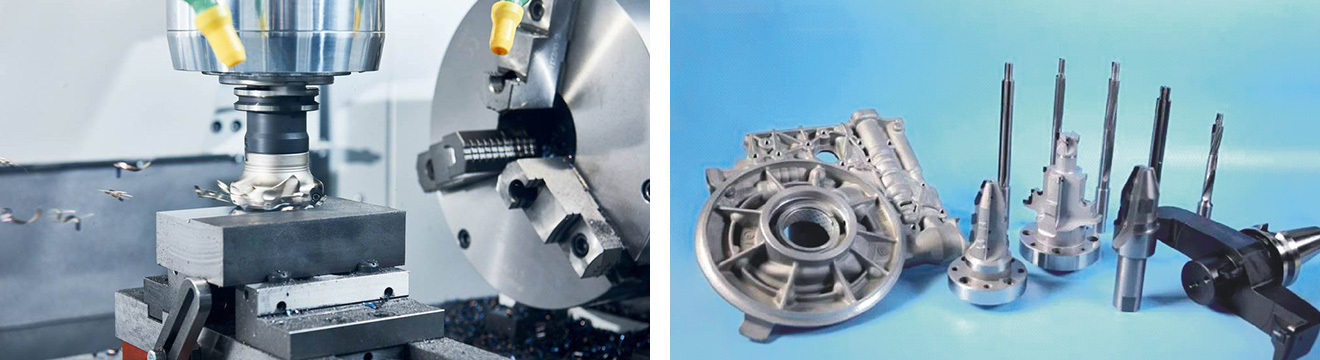

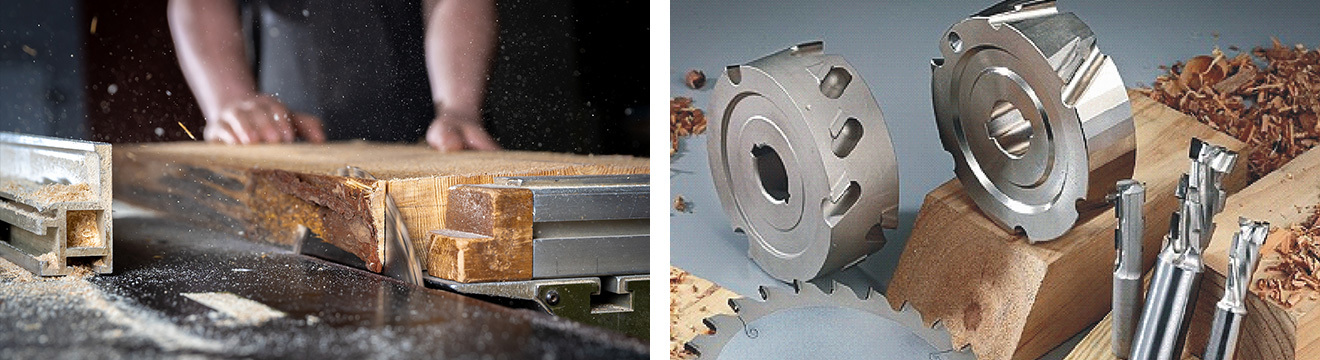

PCD (polycrystalline diamond) cutting tool blanks are primarily used for cutting and machining nonferrous metals and alloys, such as Si/Al alloys, aluminum, copper and similar metal alloys . They are also used to machining nonmetallic materials such as wood, graphite, ceramics, plastic, rubber, and so forth, where high abrasion resistance and long life are required.

SFD focuses on developing new PCD cutting tool blank grades which are suited to cutting and machining the variety of new and emerging materials in industry, and for tools targeted to meet our customers’ needs.

Specification

| Grade | Average diamond grain size (μm) | Diameter (mm) | Standard overall thickness (mm) | Average PCD thickness (mm) | PCD surface |

| GC001 | 1 | 58 | 1.6, 2.0, 3.2 | 0.5 | Polished or unpolished |

| GC002 | 2 | 58 | 1.6, 2.0, 3.2 | 0.5 | Polished or unpolished |

| GC005 | 5 | 58 | 1.6, 2.0, 3.2 | 0.5 | Polished or unpolished |

| GC010 | 10 | 58 | 1.6, 2.0, 3.2 | 0.5 | Polished or unpolished |

| UA010 | 10 | 58 | 1.6, 2.0, 3.2 | 0.5 | Polished or unpolished |

| GD025 | 25 | 58 | 1.6, 2.0, 3.2 | 0.5 | Polished or unpolished |

| GA025 | 25 | 58 | 1.6, 2.0, 3.2 | 0.5 | Polished or unpolished |

| GM253 | 25+3 | 58 | 1.6, 2.0, 3.2 | 0.5 | Polished or unpolished |

| GM302 | 30+2 | 58 | 1.6, 2.0, 3.2 | 0.5 | Polished or unpolished |

1). Special overall thickness, such as 0.8mm. 1.0mm, 1.2mm, 2.5mm, etc. are available for customization.

2). Special PCD thicknesses are also available for customization.

3). Both regular and irregular PCD cut tips in various shapes or profiles are available in accordance with customers’drawings.

Advantage

1. Strong R&D capability in developing the right grades to meet customer's specific applications.

2. Strong R&D capability in developing the large disc in China.

3. Wide PCD grain sizes from sub-micron to rough micron are available for all woodworking and metalworking applications.

4. Very strong production capability assures very fast delivery for PCD discs and cut tips.

Application Area

SFD PCD cutting tool blanks are widely used in various industries:

1.Metalworking Industry: Automobile etc.

Many grades of SFD PCD cutting tool blanks are good for tooling various materials in automobile industries.

Our sub-micron PCD is mainly for low Si content alloys to obtain good surface finish. The fine micron PCD series are recommend in processing low Si content Al alloys, copper & copper alloys.The middle microns are mainly for 12% Si/Al alloys work pieces. The mixed microns and rough microns are good for tooling 12% Si/Al alloys work pieces, cast iron, carbide, CFRP, titanium and metal matrix composites, etc.

2.Woodworking Industry

SFD PCD cutting tool blanks fine micron series are suitable for processing solid wood, bamboo, plastic. Medium grain sizes are good for general applications for chipboard, wood composite, MDF, laminate flooring, etc. The mixed and rough grades are mainly for HPL veneer floor, PVC floor, MDF/HDF, and reinforced particle panels.

3.Electronic industry (3C)

SFD PCD products in medium fine grain sizes are also applicable for processing mobile phone frame, key, electronic circuit boards, etc., which require better surface finish.

4.Building materials industry

SFD PCD products in medium coarse grain sizes are also widely used for processing different materials in building & constructing industry, such as graphite, stone, carbon fiber composite materials, etc., which require higher wear resistance tools.

Related documents

Inquiry And Quote

Related Products