CBN

Category

PCBN Blanks For Cutting Tools

Advisory

Advisory

Description

SFD PCBN, with characteristic of high hardness, high wear resistance and high thermal stability, is made of selected CBN powder and sintered at high pressure and high temperature, with metals or ceramic binders. CB series is composed of CBN layer and tungsten carbide base.

Application

SFD PCBN is ideal for tools in machining of high hardness and hard processed ferrous materials (HRC45-65), such as hardened steel, gray cast iron, heat resistant alloy, high-speed steel, hard facing alloys, Ni-Cr alloy, powder metallurgy metals. PCBN is typically used to machine brake discs, engine blocks, engine cylinder liners, brake drums, flywheels, valve seats and guides, gears, mold and die parts, etc.

Specification

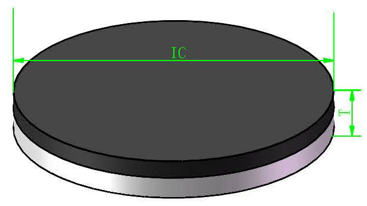

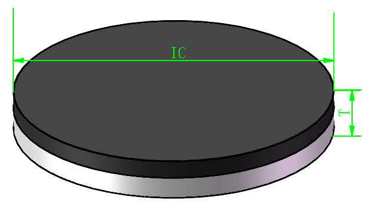

| Carbide backed PCBN disc | ||||

| Disc | Dimensions(mm) | Grade Available | ||

| Diameter(D) | Thickness (T) | ||

| 58 | 1.6/2.4/3.2/4.8 | CB960,CB900, CB720, CB500 | ||

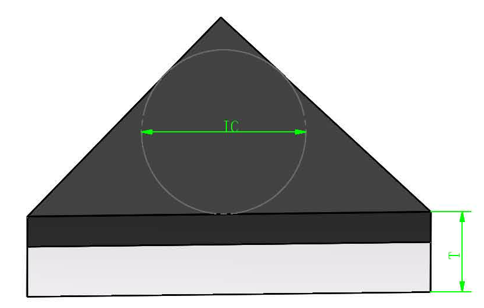

| Carbide backed PCBN semi-finished inserts | ||||

| Shape | ISO | Dimensions (mm) | Grade Available | |

| IC | Thickness(T) | |||

| Rounds | RNUN-0903XX | 9.8 | 3.2 | CB960,CB900, CB720, CB500 |

| RNUN-1203XX | 13 | 3.2 | |

| RNUN-1204XX | 13 | 4.76 | ||

| RNUN-1904XX | 19.4 | 4.76 | ||

| Squares | SNUN-0603XX | 6.7 | 3.2 | CB960,CB900, CB720, CB500 |

| SNUN-0903XX | 9.8 | 3.2 | |

| SNUN-1203XX | 13 | 3.2 | ||

| SNUN-1204XX | 13 | 4.8 | ||

| Triangles | TNUN-1103XX | 6.7 | 3.2 | CB960,CB900, CB720, CB500 |

| TNUN-1603XX | 9.9 | 3.2 | |

| TNUN-2204XX | 13.2 | 4.8 | ||

Advantage

1. Multiple grades of PCBN blanks and wide range of application

2. High cost-effective, Easy Processing, good performance, High wear resistance, Consistence

3. The disc diameter (58 mm) of PCBN produced in China

4. Strong technical support, Customized R&D PCBN and service

5. Strict quality management system to guarantee the consistent quality

6. Short lead time: 1-2 days for PCBN Disc. 3-4 days for 10,000 pieces of PCBN tips

Application Area

SF-Diamond PCBN (polycrystalline cubic boron nitride) is ideal for tools used to machine hard ferrous metal items (HRC45-65) such as high speed steel, bearing steel, cast iron,etc.

It’s typically used to machine brake discs, engine blocks, engine cylinder liners, brake drums, flywheels, valve seats and guides, gears, mold and die parts etc.The surface finish of the workpiece is good, which can replace grinding with turning, greatly improve labor efficiency and effectively reduce production costs.

Related documents

Inquiry And Quote

Related Products